| Bray

Yacht Design and Research Ltd. White Rock, B.C. |

|

Long range cruisers have taken over as the most popular type of vessel being sold today. Fish boats of the world are the first to be copied as character vessels and examples of rough, tough, ocean going ships. Then comes the fine tuning of features to meet the unique requirements of pleasure craft utilizing the innovations of the last decade to enhance seakeeping and efficiency. From this evolution comes a fresh breed of craft uniquely sculpted to fit the stringent requirements of a serious offshore cruiser. And with these new vessels come features which have the boaters asking: "How do they work? Why is it some boats have them and others do not? Can they be added to my boat? How much will it cost to install? What if it ruins my boat?" One of these features stands out in it's promise to save money and improve comfort at sea. The bulbous bow has created a growing interest among the cruising fraternity. All the latest and greatest have them, and those that don't, want them. Techno-babble abounds, yet little is known and much is claimed. "It will save you a fortune in fuel, you can cruise for free, they only work in special cases, or it will weigh you down like an anchor" are just a few of the comments you may have heard. What is a bulbous bow? In the late 1950s research was undertaken to reduce the drag on large commercial cargo ships. Many different ideas were tried and continue to be tried today in the ongoing development of the science of Naval Architecture. With model testing and advanced knowledge of hydrodynamics, the bulbous bow was formulated typically giving a 5% reduction in fuel consumption over a narrow range of speed and draft. This was significant for a large ship crossing vast oceans at a time when the cost of fuel was rising. Unfortunately, this was not enough to make it worthwhile for smaller yachts racing around the bay. Also, the narrow range of displacement speed was not in keeping with the yachtsman's need for speed on the water. As the market for displacement long range cruisers opened up, innovative builders began to look for answers to their consumers questions. The bulbous bow stood out as a prime solution.  Although available in many shapes and sizes, generally the bulb looks like a section of large diameter pipe with a domed end sticking out of the bow of the boat, underwater. Side bulbs, bilge bulbs, and even stern bulbs have been tried but the most consistent results have been achieved with bow bulbs. Today, to see a large ship without a bulbous bow is a rare sight indeed. Their results have been proven over countless thousands of deep ocean miles in all kinds of weather by all kinds of vessels. How big is big and how small is small? With the success of larger ships, smaller and smaller vessels started looking for the same results. Here on the West Coast where the fishing fleets run great distances over open ocean from California to Alaska, the desire for economy spurred optimization of the bulbous bow. The large ocean trawlers and packers were first, followed by most of the fishing fleet. In the late 1980s the University of British Columbia, utilizing the B. C. Research Ocean Engineering Center, initiated model test work on 60 foot fishing seiners. Since that time, B.C. Research has become the center of bulbous bow technology, doing model test work for yacht builders and commercial yards alike as well as for designers and researchers. Results have shown that the continuous displacement speeds that are run for days at a time, coupled with the limited change of draft, make long range motoryachts ideal for this application. Vessels as small as the 46 foot Nordhavn have had bulbs fitted. Below this size the bulb's effectiveness seems to be lost, however. Over 45 feet the results are adequate and closer to the 60 foot size real gains are being achieved. This may be due to the lack of detailed research conducted on vessels under 45 feet or just because of the stockier hull forms required in these really small ships. It is possible that the stocky hull form commonly used is not compatible with the characteristics that make the bulb work. Possibly, development of a new hull form may be required in vessels under 45 feet to benefit fully.  Power boats are not the only ones to take advantage of the bulb. Motorsailers have also been known to indulge in the bulge. So much work has been done with various configurations, shapes, and sizes, that an average bulb can be designed for displacement vessels with fairly predictable results. Detailed information is required about the vessel's hull form, area of midsection, etc. The more accurate the information, the better the results. For maximum benefit model testing is still required to fine tune the proportions to the hull form. It is also an opportunity to preview the results before the work is preformed on the full size vessel. Model test results are typically within 2% of the full size results. So what's in it for you? The benefit of a modern-day bulbous bow will reduce your fuel consumption 12% to 15%, give you the equivalent greater range, or higher speed, whichever you choose to use. The greatest amount of benefit will be at the high end of the displacement speed range, reducing as your speed decreases. At higher speeds wave making resistance accounts for the greater portion of the drag, and the slower you go proportionally more of the resistance is taken up by wetted surface drag. At low speed (around 6 knots and lower) the bulb will even cause an increase in drag because of it's greater wetted surface area. Luckily at that low speed the added power consumption is negligible and generally little time is spent in this speed range. In addition, you will find increased seakeeping ability due to dampening of the pitching motion. When charging into head seas there is the chance of slamming the bulb on the troughs, but this is limited to a very narrow range of wave train and heading. A slight change in direction and/or speed will cure this ill-effect. Boats that anchor off the stem will find the bulb with a direct hit every time and will need to consider an anchoring bowsprit. Anchor pockets port and starboard are the ideal situation but still the chain may grate from time to time if you are doing considerable swinging. I have also been told that in clear water some people are offended by the symbolic shape below.

CUSTOM 65' STEEL YACHT  Who can and who can't? Any displacement vessel, regardless of size, material, or age can be retrofitted with a bulb. The question is; will the cost exceed the benefit? Bulbs have been built out of steel, aluminum, fiberglass, and wood. For an existing boat they are attached externally to the bow creating a bumper. If damaged they do not breach the watertight integrity of the hull. They can be fabricated out of pipe with a domed cap, they can be shaped out of foam and fiberglassed, or any combination that will produce a strong, smooth structure. Once properly designed any shipyard can create and install one in a short period of time with the vessel out of the water. Factors that can complicate the installation are bow thrusters that occur within the outline of the bulb and transducers and thru- hulls that have to be moved or extended to reach the new vessel skin.

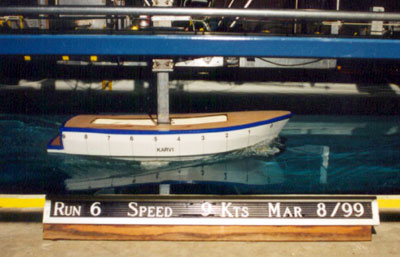

How does it work? Although much is known about the bulb, much of it's functions are still in dispute. To say that on a hydrodynamic level, the destructive interference of the primary and secondary wave trains causes an overall reduction in drag which is beneficial to the vessels resistance characteristics, would be true. A bit of a mouth full, but true! Or on a more physical level, that the water coursing over the top of the bulb is exerting a downward pressure that is keeping the stern from squatting, thereby allowing flatter trim, causing the vessel to run with less resistance. Still others would argue the finer points of laminar flow, with no clear conclusions. In any case, it is a fact that bulbs do work, and in some cases reduce resistance as much as 25%. Their proportions are derived from the features and dimensions of the vessel itself. The diameter (volume) is a direct result of the hull midship area. The length is determined by the stem profile, as the farther forward the bulb extends the more leverage it has but is generally kept shorter than the bow overhang. The vertical placement is calculated so the bulb is just below the surface where it will create a wave in front of the ship interfering with the natural wave train of the vessel, creating a wave hollow where a crest should be. In this way the vessel will run flatter and the overall wave height will be reduced. The vessel will pitch less which will cause less disturbance in the water and the passage of the vessel through the water will be achieved with less fuss and muss. Any time a vessel can be moved through the water with less waves and overall disturbance to the surface less power has been transmitted to the water to create those waves. To be able to move a vessel through the water with no perceptible notice of its passage is the (as yet unattained) ultimate goal of all Naval Architects and the ultimate in power savings.  TEST RUN WITH BULB In Conclusion . . . If your craft is over 45 feet in length and is a displacement vessel, (i.e. it does not go faster in knots than 1.5 times the square root of it's waterline length), and you plan on doing some very long passages at a constant speed then you should consider a bulbous bow. What is your next step? Contact a Naval Architect who is knowledgeable about bulb technology. Be prepared to give him serious technical data on your vessel, or if you don't have the data, you will have to pay someone to re-establish that information. If you are willing to go with a bulb of standard proportions and form, no model testing will be necessary. What are the costs? You are looking at 20 - 30 hours of a professional's time at his going rate to design the proportions of the appendage. A drawing showing details of actual construction may cost more on top of that. Estimate your time, then build it yourself or have a shipyard give you a quote and then do the work. Remember that the form can be achieved any number of ways economically. In order to achieve your desired results, the finished product must be securely attached to the hull, strong, smooth, and aligned with the boat's centerline. Just add large amounts of ocean water and minimal amounts of power and many happy, inexpensive years of cruising lie before you. Bon voyage! Patrick J. Bray |